[Copy] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Yokutidwa Gulu 8.8 10.9

[Copy] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Yokutidwa Gulu 8.8 10.9

Kufotokozera

ONANGAYankho

ONANGANdemanga

ONANGAKutumiza

OKONZEKA KUTUMIKIRA SOMBO

10000+ SKU mu nkhokwe

Timadzipereka pazinthu za RTS:

70% zinthu zoperekedwa mkati mwa masiku 5

80% zinthu zoperekedwa mkati mwa masiku 7

90% zinthu zoperekedwamkati mwa masiku 10

Maoda ambiri, chonde lemberani makasitomala

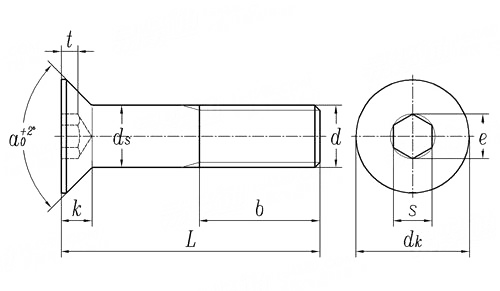

| d | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | |

| P | Phokoso | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| α | mtengo (+2) | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 60° | 60° |

| b | L≤125mm | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 |

| 125<L ≤200 | / | / | / | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | |

| L>200 | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | |

| dk | Max=Mwadzina | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| Min | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

| ds | Max=Mwadzina | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Min | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | |

| e | Min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | 16 | 16 |

| k | Max | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 13.1 | 14 |

| s | Mwadzina | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| Min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | 14.032 | 14.032 | |

| Max | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.212 | 12.212 | 14.212 | 14.212 | |

| t | Max=Mwadzina | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 | 10.3 |

| Min | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 | 9.87 | |

Kufotokozera mwatsatanetsatane

Zomangira zolimba kwambiri zimatulutsa crispness zikamathiridwa. Amafunika chisamaliro chapadera.

Hydrogen embrittlement nthawi zambiri imadziwika ndi kuchedwa kusweka pansi pa kupsinjika. Pakhala akasupe agalimoto, ma washers, zomangira, akasupe a pepala ndi zida zina zopangira malata, patangotha maola angapo msonkhano utasweka, gawo losweka la 40% ~ 50%. Pogwiritsa ntchito mbali za cadmium-zokutidwa ndi chinthu chapadera, panali kusweka kwa batch, ndipo vuto lalikulu la dziko linathetsedwa ndipo njira yolimba ya dehydrogenation idapangidwa. Komanso, pali ena haidrojeni embrittlement sasonyeza anachedwa fracture chodabwitsa, monga: electroplating hanger (zitsulo waya, waya wamkuwa) chifukwa cha nthawi zambiri electroplating ndi pickling plating, wa hydrogen malowedwe kwambiri, nthawi zambiri kuoneka ntchito khola zidzachitika Chimaona fracture chodabwitsa; Mfuti ya mfuti, itatha kangapo kuphulika, inagwa pansi ndikusweka; Ziwalo zina zozimitsidwa (kupsinjika kwakukulu kwamkati) zidzasweka pamene pickling. Zigawozi zimakhala ndi hydrogenated kwambiri ndipo zimasweka popanda kupsinjika kwakunja, zomwe sizingagwiritsidwenso ntchito kubwezeretsa kulimba koyambirira ndi dehydrogenation.

The apamwamba zakuthupi mphamvu, wamkulu wa hydrogen embrittlement tilinazo. Ili ndi lingaliro lofunikira lomwe liyenera kufotokozedwa ndi akatswiri azachipatala akamalemba ndondomeko ya electroplating. Zitsulo zokhala ndi mphamvu zolimba σb>105kg/mm2 zomwe zimafunidwa ndi miyezo yapadziko lonse lapansi ziyenera kukhala ndi nkhawa zisanakhazikike komanso chithandizo cha post-plating dehydrogenation moyenerera. Makampani oyendetsa ndege aku France amafunikira chithandizo chofananira cha dehydrogenation pazigawo zachitsulo zokhala ndi mphamvu zokolola σs> 90kg/mm2.

Chifukwa makalata abwino pakati pa chitsulo mphamvu ndi kuuma, ndi mwachilengedwe komanso yabwino kuweruza tilinazo wa hydrogen embrittlement wa zinthu ndi kuuma kuposa mphamvu. Chifukwa chojambula changwiro cha mankhwala ndi makina opangira makina ayenera kulembedwa ndi kuuma kwachitsulo. Mu electroplating, tinapeza kuti kuuma zitsulo mozungulira HRC38 anayamba kusonyeza chiopsezo hydrogen embrittlement fracture. Pazigawo zokwera kuposa HRC43, dehydrogenation iyenera kuganiziridwa pambuyo poyala. Kuuma kukakhala pafupi ndi HRC60, chithandizo cha dehydrogenation chiyenera kuchitidwa mwamsanga pambuyo pa chithandizo chapamwamba, apo ayi zitsulo zidzang'ambika mkati mwa maola ochepa.

Kulongedza

Zambiri zaife

* Chithunzi chotsatirachi chikuwonetsa ma incoterms osiyanasiyana. Chonde sankhani yomwe mukufuna.

NTCHITO YOTENGA ZONSE

Quality Choyamba, Chitetezo Chotsimikizika

![[Copy] DIN7991 Hex Socket Countersunk Screw Gulu la Carbon Steel Zinc Yopukutidwa Gulu 8.8 10.9 Chithunzi Chowonetsedwa](https://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-1.jpg)

![[Copy] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Yokutidwa Gulu 8.8 10.9](https://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-1-300x300.jpg)

![[Copy] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Yokutidwa Gulu 8.8 10.9](https://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-3-300x300.jpg)

![[Copy] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Yokutidwa Gulu 8.8 10.9](https://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-4-300x300.jpg)

![[Copy] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Yokutidwa Gulu 8.8 10.9](https://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-6-300x300.jpg)

![[Copy] DIN7991 Hex Socket Countersunk Screw Grade Carbon Steel Zinc Yokutidwa Gulu 8.8 10.9](https://cdn.globalso.com/hongjifasteners/Hex-socket-countersunk-screw-ZP-5-300x300.jpg)